Successful case of Force Monitoring System

Introducing examples of cutting-edge smart factory construction, which 3View has been leading in various industries.

Successful case of Force Monitoring System

Introducing examples of cutting-edge smart factory construction,

which 3View has been leading in various industries.

Quality and Productivity Is it possible to catch the best of both worlds?

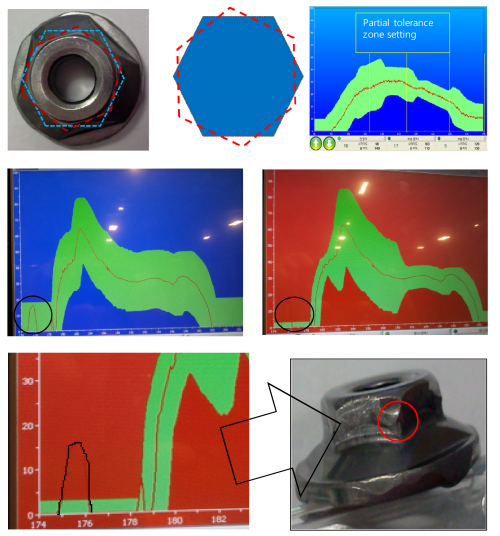

“C company in America which is the first vendor for Toyota had the case that the head part of a nut was omitted in production, due to the unsmooth transference and sometimes the nut was made wrongly in the tool, due to the slopingness.

Increasing the degree of precision stops machines more often which leads to the lower productivity and on contrary to this, lowering the degree of precision leads to the lower quality eventually, so C company seeks a solution from us.

Finally, They met their demand keeping productivity by utilizing Machineview™’s function called “partial tolerance zone” which reinforces the monitoring function.

Innovative tool life span extension!

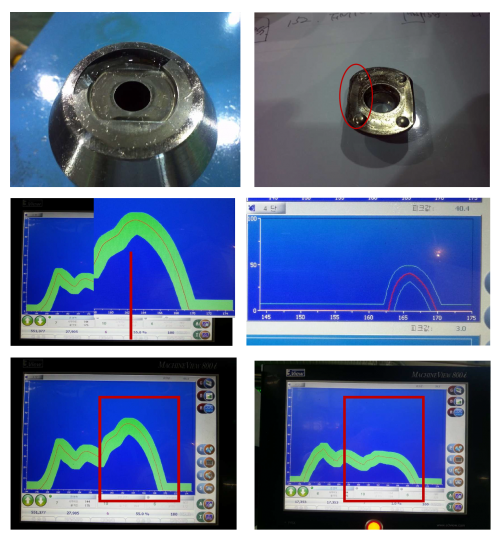

D factory located in Korea had the case that they had wrong flanges, even the tolerance zone was within the monitoring range. Figured out that the punch and dies had a collision, plus, due to this, the tool had been abnormally stressed. The solution was that the monitoring system detects collision between tools in advance, thanks ato this monitoring detection way, the tool life span became 700,000 pcs now! (The average tool life span was from 80,000 to 150,000 pcs.)

F company located in Japan – MachineView™ + Tool life span management since 2017.

Development background

- Change – measuring method from handwrite to computerized system to grasp correct information and improve on inefficiency. Necessity for innovation on tool life span management way. Prevention for tool breakage in advance, manage the tool change period based on statistical system.

Result

- Improvement on productivity – minimization on down-time through tool life span management program. Efficiency on production management – enable to manage tools based on numerical statistics, grasp tool stock and arrange the production plan based on demand quantity-calculation. Cost reduction – through tool life span extension.